In the world of cutting tools, versatility is highly valued. That's where combo blades come into play, offering the convenience of multiple cutting applications in a single tool. In this blog post, we will dive into the realm of combo blades, exploring their features, benefits, and how they can optimize your cutting tasks. Discover the power of these versatile cutting tools and unlock a new level of efficiency in your projects.

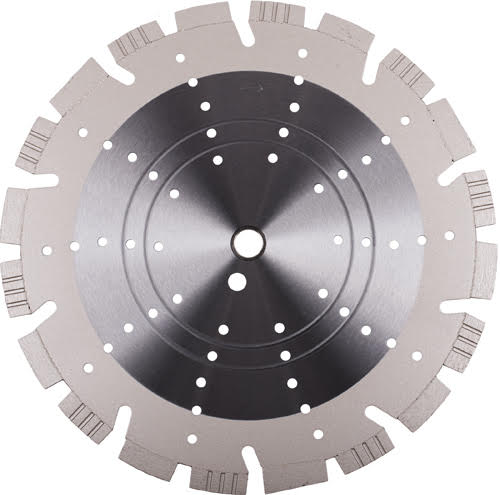

1 - Understanding Combo Blades: Combo blades, also known as multi-purpose blades, are designed to perform different cutting tasks with ease. These blades are engineered to tackle various materials, such as wood, metal, and plastic, making them an all-in-one solution for a wide range of applications.

2 - Key Features and Benefits:

a) Cutting Versatility: Combo blades are equipped with specially designed teeth that enable them to handle different materials. The blade may have a mix of ripping and crosscutting teeth, allowing you to switch seamlessly between tasks without changing blades.

b) Time and Cost Savings: By eliminating the need for multiple blades, combo blades streamline your cutting process and save you time and money. Whether you're working on a woodworking project or tackling DIY repairs, having a single blade that can handle different materials means you won't have to switch blades frequently.

c) Optimized Performance: Combo blades are engineered to deliver optimal performance across various cutting applications. They are designed to provide clean and precise cuts, ensuring professional results in every task. The versatility of combo blades also makes them an excellent choice for contractors and DIY enthusiasts alike.

3 - Selecting the Right Combo Blade:

a) Consider the Materials: Evaluate the types of materials you frequently work with to determine the blade's tooth configuration and durability needed for your projects.

b) Blade Size and Arbor: Ensure the combo blade you choose is compatible with your power tool by considering the blade size and arbor requirements.

c) Safety Considerations: Always prioritize safety when selecting a combo blade. Look for features like anti-kickback design and vibration reduction to enhance user safety during cutting operations.

4 - Best Practices for Using Combo Blades:

a) Proper Blade Installation: Follow the manufacturer's instructions for installing the combo blade securely and aligning it correctly with your power tool.

b) Adjusting Blade Height and Angle: Make necessary adjustments to the blade height and angle based on the material being cut, ensuring optimal cutting performance and minimizing risks.

c) Regular Maintenance: Keep your combo blades in top condition by cleaning them after each use, removing any debris or pitch buildup. Sharpen or replace the blade as needed to maintain optimal cutting performance.

Combo blades offer a practical and efficient solution for various cutting tasks, providing versatility and optimized performance. By understanding the features and benefits of these multi-purpose blades, selecting the right one for your needs, and following best practices for usage and maintenance, you can enhance your cutting experience and achieve outstanding results across different materials. Embrace the power of versatility with combo blades and unlock new possibilities in your cutting endeavors.