When cutting unyielding materials such as concrete, asphalt, or stone, it is essential to use the proper diamond blade. A diamond blade is a specialized cutting instrument that employs a diamond to slice through difficult materials. Diamond blades appear in a variety of shapes, sizes, and compositions, making it difficult to select the appropriate one for your particular cutting needs.

This article will discuss the most important considerations when selecting a diamond blade for your cutting requirements.

Determine the Cutting Material

The first step in selecting the appropriate diamond blade is determining the material to be cut. Different materials have varying degrees of hardness and require various varieties of blades. For instance, cutting asphalt or stone requires a different blade than cutting concrete. The following are prevalent materials and the blades used to cut them:

- For cutting concrete, diamond blades with a hard bond are the finest option. These blades are designed to cut through the concrete's tough aggregate.

- For cutting asphalt, diamond blades with a soft bond are the finest option. These blades are designed to cut through asphalt's weaker aggregate.

- For cutting stone, diamond blades with a medium bond are the finest option. These blades are designed to penetrate the abrasive and unyielding nature of stone.

Select the Correct Blade Size

The size of the blade you select will depend on the type of cutting task you are completing. The deeper the incision, the larger the blade. Consider the following factors when selecting the correct blade size:

- Depth of Cut: If you need to cut deeply into a material, a larger blade will be required. If you're carving concrete for a foundation, for instance, you'll need a blade that can cut at least 6 inches deep.

- Tool Size: The size of your cutting instrument also plays a role in determining the size of the blade you select. Choose a blade that is compatible with your cutting instrument.

- Project Size: Consider using a larger blade if your cutting endeavor is substantial. By allowing you to cut larger areas simultaneously, this can save you time and effort.

Consider the Diamond Blade Type

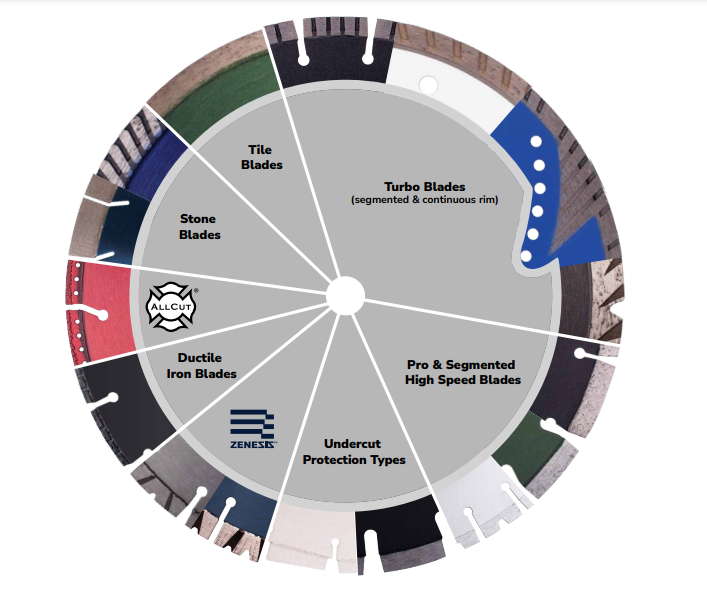

There are various varieties of diamond blades, each designed for specific cutting applications. Here are some prevalent diamond blade types and their applications:

- Segmented Blades: Segmented blades have diamond segments that are separated by openings. These blades are optimal for cutting through difficult materials such as asphalt and concrete.

- Continuous Rim Blades: Continuous rim blades lack perforations and have a continuous edge. These blades are perfect for cutting delicate materials such as tile and porcelain.

- Turbo Blades: Turbo blades feature a serrated rim that aids in blade cooling and prevents overheating. These blades are optimal for cutting through abrasive substances such as granite and marble.

Check the Quality of the Blade

The quality of the blade you select can affect the precision and durability of your incisions. Consider the following factors when evaluating the grade of a diamond blade:

- Diamond Quality: The lifespan of the blade and the quality of the incisions are affected by the quality of the diamond used in the blade. Look for a blade with evenly distributed diamonds of superior quality.

- Blade Hardness: The blade's hardness impacts its durability and performance. Consider a blade whose hardness corresponds to the material being cut.

- Blade Thickness: The blade's efficacy and durability are affected by its thickness. Find a blade whose thickness corresponds to the scale of the project you're working on.

Consider the Speed of the Blade

Blade speed can influence the quality of your incisions and the blade's durability. Consider the following factors when selecting a blade speed:

- Cutting Speed: If you need to rapidly cut through a material, you will require a blade with a high cutting speed. However, a higher cutting speed can reduce the blade's durability.

- RPM: The RPM (revolutions per minute) of the cutting instrument also affects the speed of the blade. Choose a blade that is compatible with the RPM of your cutting instrument.

- Cooling: During use, blades can become overheated, which can affect the quality of the incisions and the blade's durability. Look for blades with cooling holes or slots to aid in heat dissipation and keep the blade cold while in use.

Choose the Appropriate Blade for the Task

Selecting the optimal diamond blade for the task can help you achieve the best possible cuts and save you time and money over time. Consider the following factors when selecting the appropriate blade for your cutting task:

- Budget: When selecting a blade, it is necessary to consider your budget, as diamond blade prices can vary. A higher-quality blade may save you money in the long run by lasting longer and generating better cuts than a cheaper blade.

- Cutting Conditions: The conditions under which you are cutting can also influence the type of blade you select. For instance, if you are cutting in damp conditions, you may require a blade with anti-slip characteristics.

- Safety: Always put safety first when selecting a diamond blade. Choose a blade that is compatible with your cutting instrument and observe all safety precautions and guidelines when using the blade.

Consider the Cutting Operation Type

The type of cutting operation being performed can also influence the blade selection. Here are some prevalent cutting operations and the blade types that correspond to them:

- Wet Cutting: In wet cutting, water is used to chill and lubricate the blade throughout the cutting process. To enable for water flow, wet-cutting blades are typically softer and have fewer diamonds.

- Dry Cutting: Dry cutting is the process of cutting without using water. Typically, dry-cutting blades are sturdier and contain more diamonds to withstand the heat generated during the cutting process.

- Plunge Cutting: Instead of beginning a cut at a material's border, a plunge cut begins in the center of the material. For optimal precision, plunge-cutting blades typically have a narrow profile and a high diamond concentration.

Consider the Blade's Segment Height

The segment height of a diamond blade is the height of the blade's diamond segments. Consider the following factors when selecting the appropriate segment height for your cutting project:

- Material Hardness: Harder materials necessitate a blade with a greater segment height to ensure that the diamonds can successfully cut through the material.

- Cutting Depth: If you need to cut through a material that is thicker than the diameter of the blade, you will need a blade with a higher segment height.

- Blade Lifespan: As there is more diamond material to wear down over time, a higher segment height can also increase the blade's durability.

Consider the Cutting Tool Type

The type of cutting instrument you employ can also influence the diamond blade you select. Here are some common cutting tools and the blade varieties that correspond to them:

- Circular Saws: These are frequently used to cut concrete, bitumen, and other hard materials. Circular saw diamond blades typically have a larger diameter and a higher RPM rating.

- Angle Grinder: Angle grinders are frequently utilized for carving tile, stone, and other fragile materials. Typically, diamond blades for angle grinders have a reduced diameter and lower RPM rating.

- Table Saw: Table Saws are commonly used for slicing through larger sections of material. Table saw diamond blades typically have a larger diameter and a greater segment height.

Consider the Size of the Blade's Arbor

The arbor size of a diamond blade refers to the diameter of the hole in the blade's center that fits onto the arbor of the cutting instrument. Choose a blade with an arbor size that matches the arbor size of your cutting instrument to ensure compatibility and prevent accidents.

Consider the Noise Level of the Blade

Additionally, the decibel level of a diamond blade can impact the cutting experience. Reduced-noise blades can make cutting more comfortable and reduce the risk of hearing loss. Look for blades with noise-reducing characteristics, such as vibration-damping technology or sound-absorbing materials.

Consider the Environmental Impact of the Blade

Diamond blades can have a significant impact on the environment, particularly if they are not discarded correctly. Look for blades that are made from recyclable or eco-friendly materials. Additionally, you can seek out blades with a smaller carbon imprint, which will help reduce your overall environmental impact.

Final Thoughts

Selecting the optimal diamond blade for your cutting requirements is crucial for achieving the best possible cuts and saving time and money over time. By taking into account factors such as the material to be cut, blade size, blade type, blade quality, blade speed, and job requirements, you can select a diamond blade that is optimally suited to your specific cutting needs. Always prioritize safety when using a diamond blade, and adhere to all manufacturer instructions and safety precautions to prevent accidents and guarantee the success of your cutting project.

Rogue Diamond Blades is committed to providing contractors and construction industry professionals with diamond blades of the highest quality. We recognize that time is of the essence for constantly mobile contractors. To make the purchasing procedure as simple and convenient as possible, we have designed a user-friendly website and a mobile page. So, no matter your need, Rogue Diamonds Blades can be your all-in-one shop when it comes to diamond blades!