When it comes to cutting through tough materials like concrete and asphalt, the right diamond blade can make all the difference in efficiency, cost, and overall project success. Here’s a comparison between concrete diamond blades and combo diamond blades to help you make an informed decision.

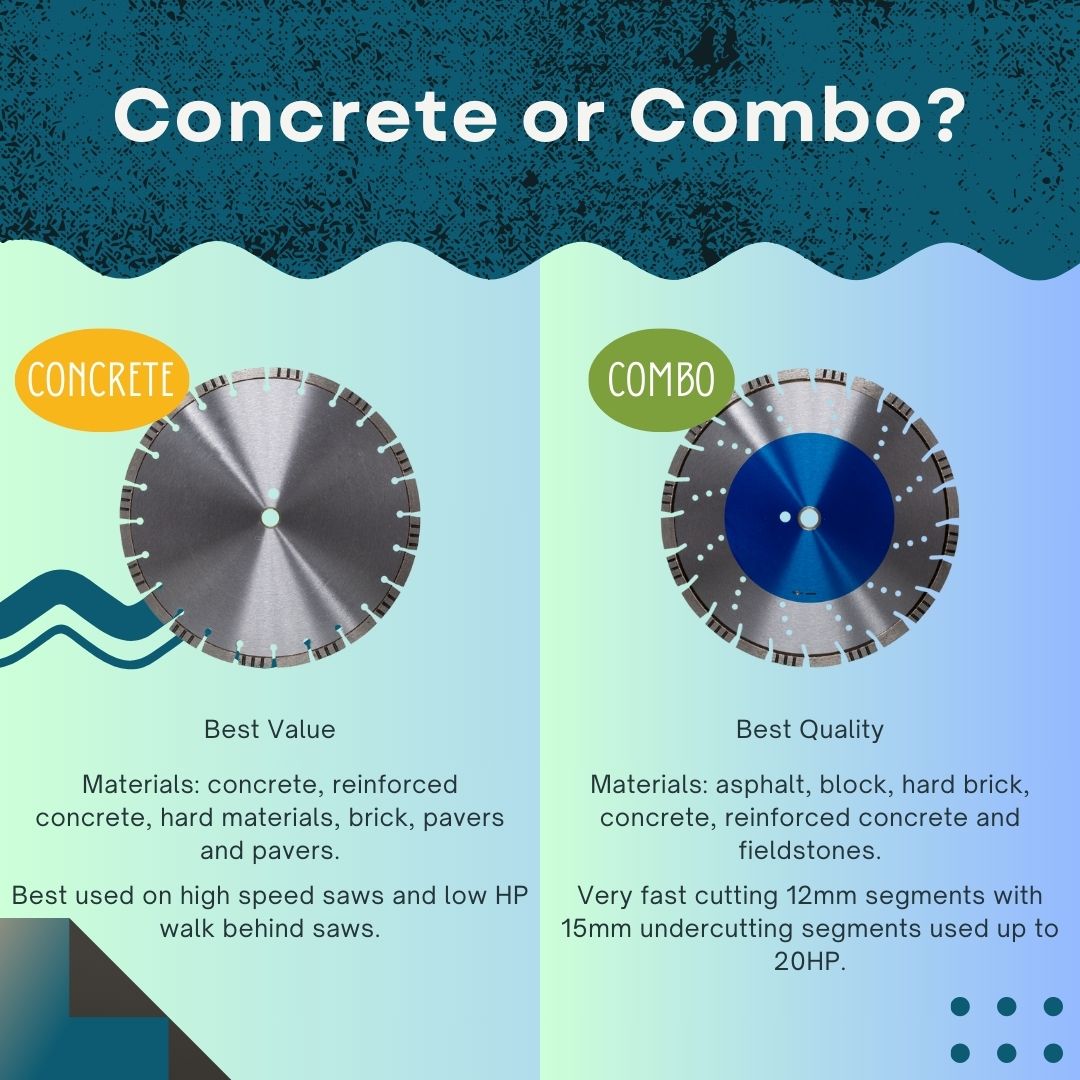

Concrete Diamond Blades

- Material Specificity: Concrete diamond blades are designed specifically for cutting concrete. They typically feature a soft bond, which allows the diamonds to wear away at the same rate as the concrete, maintaining the blade's cutting efficiency.

- Performance: These blades are optimized for the hardness of concrete and often include features like segmented rims for better cooling and debris removal. This results in faster cuts and longer blade life when cutting concrete.

- Rebar Handling: When dealing with concrete containing rebar, a continuous rim blade with water cooling is often recommended to minimize blade wear and ensure a clean cut.

- Precision and Smoothness: Concrete diamond blades provide precise and smooth cuts, reducing vibration and damage to the structure being cut.

Combo Diamond Blades

- Versatility: Combo diamond blades are designed to cut a combination of materials, most notably concrete and asphalt. They offer a medium bond, which balances the cutting needs of both hard and soft materials.

- Time and Cost Efficiency: For site work and demolition contractors, combo blades are highly beneficial as they eliminate the need to switch blades frequently, saving time and reducing the overall cost of multiple specialized blades.

- Drop Segments: Combo blades often feature drop segments that prevent undercutting when cutting asphalt, ensuring a clean and even cut.

- General Use: While combo blades can also cut other materials like brick and granite, they may not perform as well as specialized blades for these applications. However, they offer a good compromise for general use across various materials.

Key Considerations

- Material Type: If you are primarily cutting concrete, a concrete-specific diamond blade is the best choice. However, if you frequently switch between concrete and asphalt, a combo blade is more practical.

- Blade Life: Concrete diamond blades generally last longer when cutting only concrete, but combo blades offer a longer overall life when used across multiple materials.

Choosing between a concrete diamond blade and a combo diamond blade depends on your specific needs and the variety of materials you need to cut. Here are some final tips:

- For Concrete Only: Opt for a concrete-specific diamond blade for optimal performance and longevity.

- For Multiple Materials: Use a combo diamond blade for its versatility and time-saving benefits, especially in site work and demolition projects.

#Construction #DiamondBlades #ConcreteCutting #AsphaltCutting #SiteWork #Demolition #Concrete #Combo #Blades #Cutting